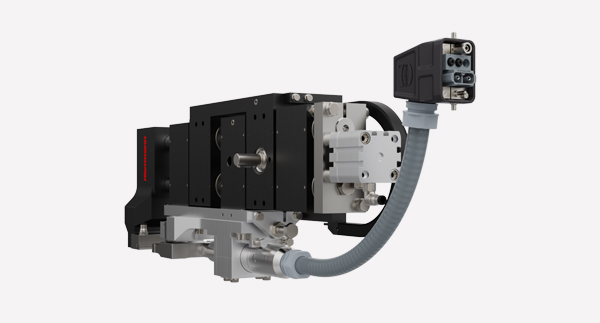

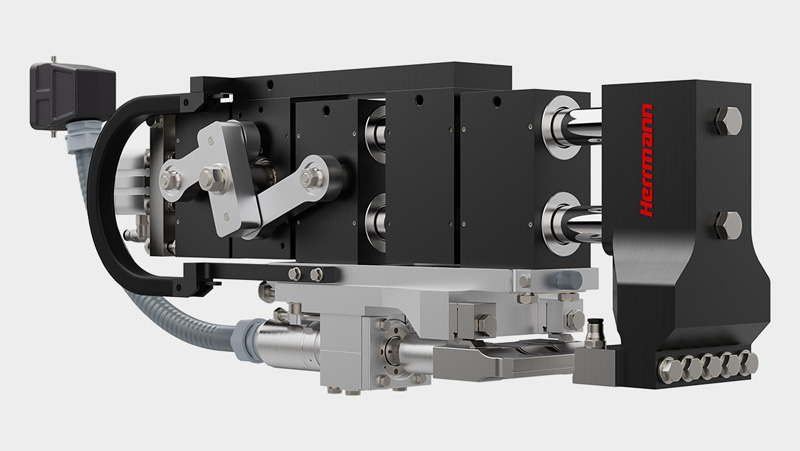

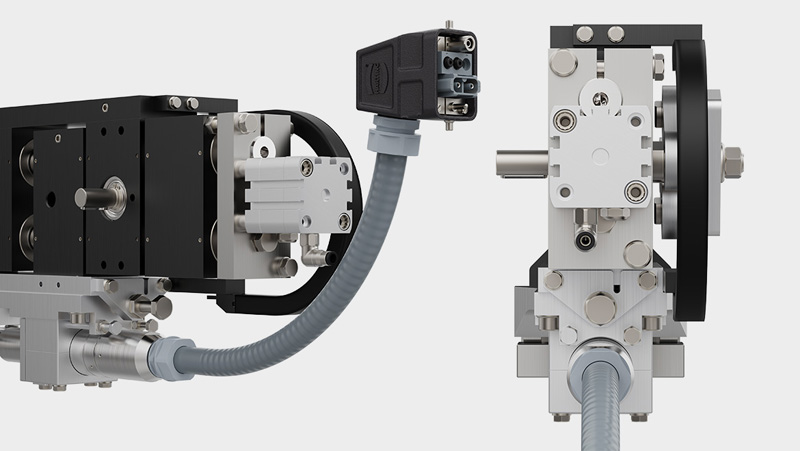

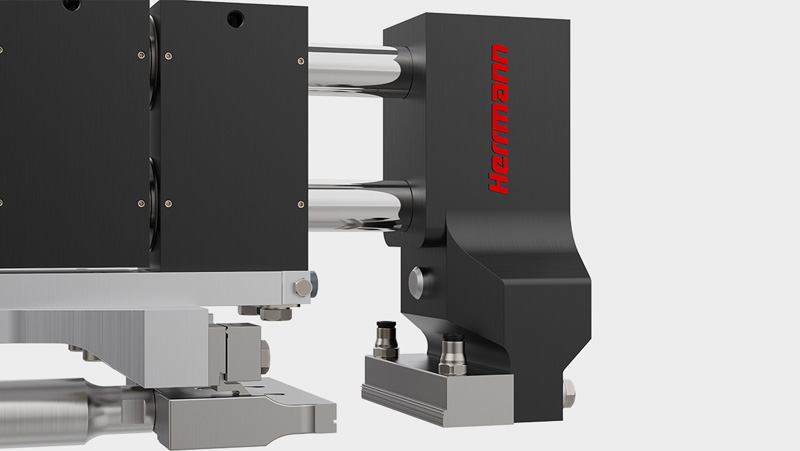

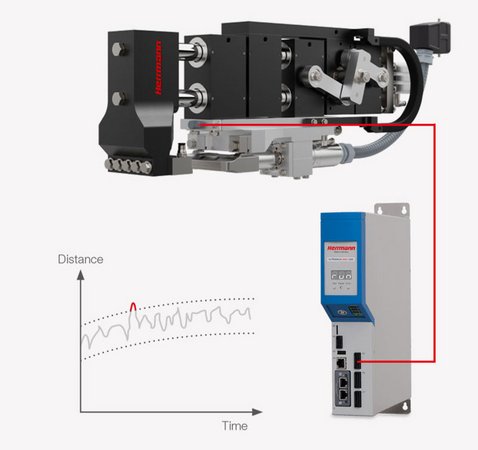

The pneumatic generation of force is integrated in the top seal module, which results in considerable freedom with regard to the drive concept. Pneumatic and electric drives can be adapted on the drive shaft. A mechanical connection with the main drive shaft of the packaging machine can also be realized. To fulfill various assembly conditions, the drive may be installed on either the left or the right side of the module – this is particularly beneficial in the case of multi-line systems.

The integrated pneumatic cylinder means that the sealing force is immediately available with the contact of the sealing tools. This PreLoaded concept allows for the process-safe sealing of pouches, also with high machine speeds.