Application Engineering

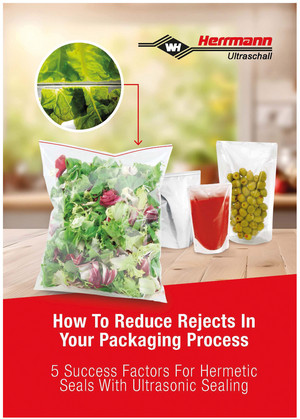

Ultrasonic sealing for a wide range of stand-up pouches

Saving resources without compromises

Valuetainable – especially when it comes to Stand-up Pouches

Stand-up pouches are a great choice for wet foods, but they may not provide complete leak-proof sealing with conventional heat-sealing methods. This can lead to waste of food and materials, as well as loss of customer trust.

Our ultrasonic sealing technology ensures tight seams and is a sustainable and cost-effective solution.

100 %

leak-proof packaging, with vibrations displacing the contents from the sealing zone.

20 x

less waste is produced by a sauerkraut packer thanks to our processing technology.

75 %

Reduce energy consumption by 75 % with ultrasonic seals.

Top seal – HFS/HFFS with cosmetic seal also for monomaterial

Technology

Seal your pouches 100 % leak-proof and meet your sustainability targets in a cost-effective manner.

Other applications that are currently under development:

- Valve Seal

- Bottom Seal

- Spout Seal

- Cross Seal

- Side Seal

INDUSTRY LEADING GUIDE

Discover how to navigate the next era of Sustainable Packaging Innovations! Don’t miss out on these game-changing insights.

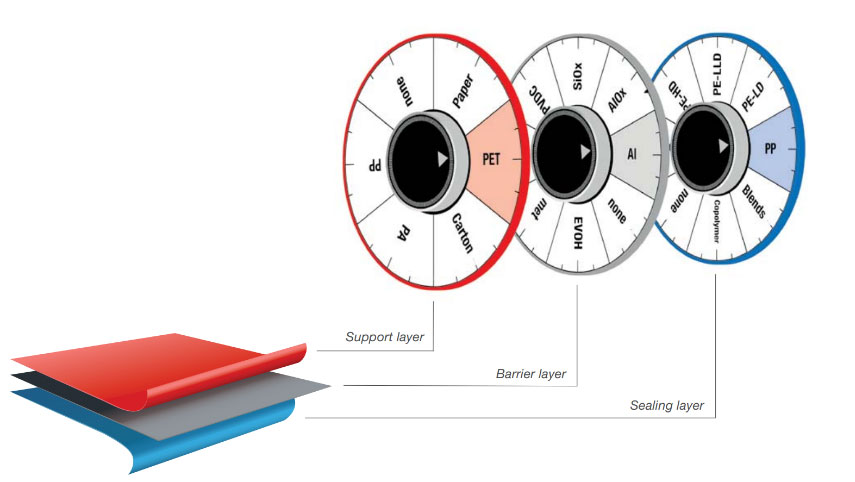

Samples of material that can be sealed with ultrasonics:

Stand Up Pouch

- PET/ALU/cPP

- BoPP or oPP/PE

- PET/ALU/PE

- oPA/PE

Applications for different filling goods:

Industry

- Wet pet food

- Ready-meals

- Sauerkraut/red cabbage

- Beverages

- Soups & sauces

- Liquid soap

- Grated cheese

Valuetainable

Upcoming EU regulations signify changes but also bring opportunities. Change now and save on essentials such as energy, CO2 emissions, raw materials, food – and costs. A sustainable and valuable choice for brands and everyone who packages.

Ultrasonic sealing offers solutions to meet the demands of the future

Legal regulation for packaging

Whether you are looking to limit overpackaging, increase the product-specific recyclate usage rate, or replace multilayer packaging with new monomaterials, ultrasonic sealing offers a future-proof solution to meet your packaging needs.

Overpacking

EU-wide standards for over-packing will define maximum allowed empty space in packaging and ban certain forms of unnecessary packaging. The Ultrasonic technology allows to minimize the sealing area and as a result reduces unnecessary packaging space.

Recyclate

In the future an increased use of recycled plastics in packaging material is mandatory to meet the legal regulations and to decrease the use of virgin materials.

Monomaterials

In order to meet future packaging recycling rates monomeric materials will become more and more a standard for packaging material. As monomeric material is quite sensible towards heat Ultrasonic offers here the right technology for a tight and reliable sealing process.

How ultrasonic sealing works

In ultrasonic welding, melt is created in the packaging material itself by introducing mechanical vibrations into the packaging material using a sonotrode. These vibrations generate friction between the molecular chains and the interfaces of the packaging material layers, resulting in localized melting. The use of cold ultrasonic tools enables rapid cooling, allowing for immediate loading of the produced seam. This minimizes the thermal load on the materials and the packaged goods.

Leverage our expertise and optimize your packaging process!

Contact us and we will launch a project together that will enable you to incorporate the sustainability megatrend into your company – conveniently, quickly, and cost-effectively.

Contact