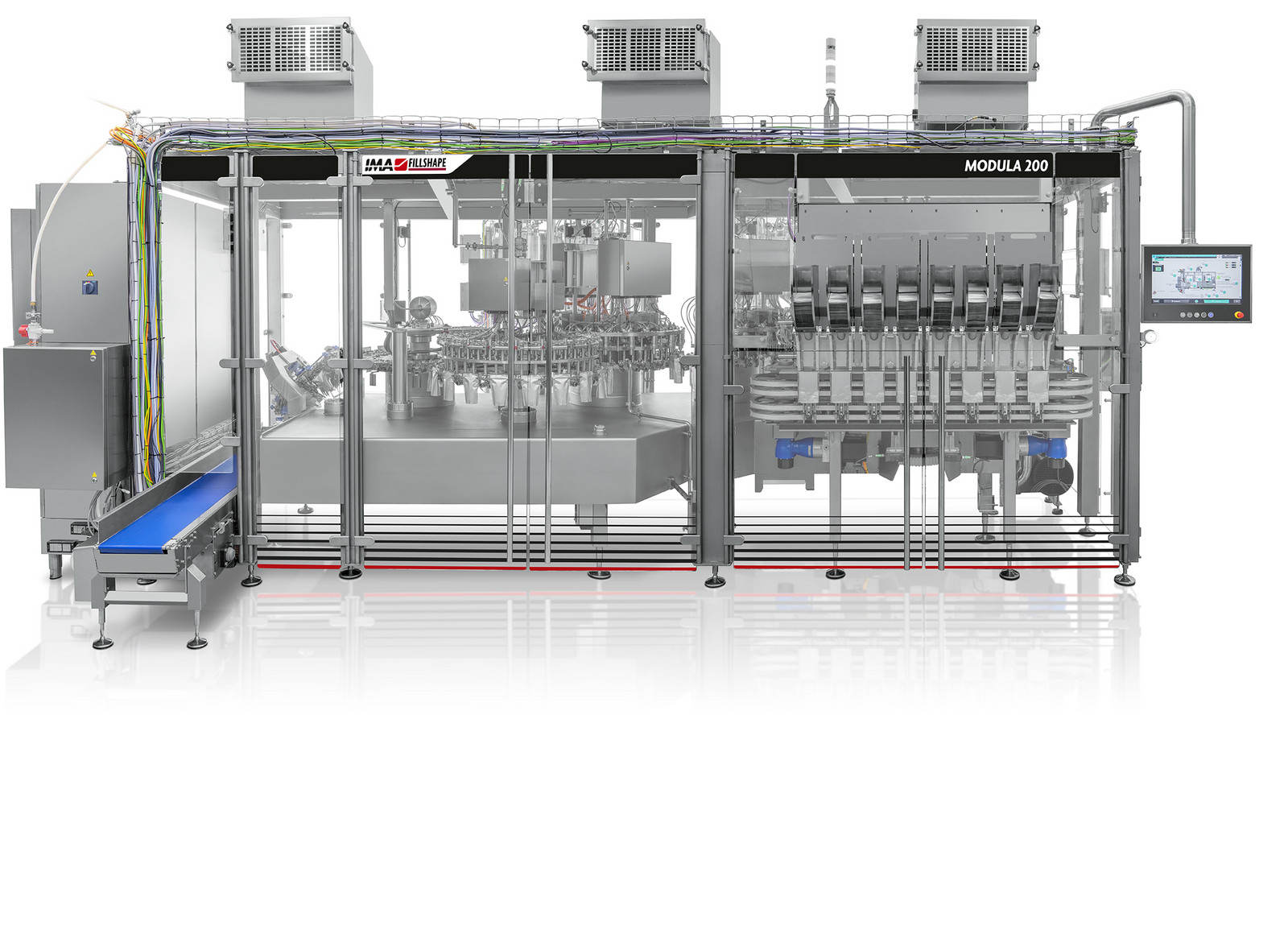

Ultrasonics in action

- Continuous motion rotary machine

- Filling and sealing of unspouted pouches

- Food, pet food & beverages

- High hygienic standards

- Huge flexibility

- Rapid changeover

- Ultimate filling accuracy

- Sealing reliability

- Boasts an extremely low rejection rate