Herrmann Ultraschall PACKAGING

Ultrasonic sealing

for your future-proof

packaging

Customer Value Leader

Herrmann Ultraschall

The customer value leadership of Herrmann in the packaging industry is driven by understanding the business of our customers and their needs. The solutions we provide help our customers to increase their sustainability and profitability.

Valuetainable

Upcoming EU regulations signify changes but also bring opportunities. Change now and save on essentials such as energy, CO2 emissions, raw materials, food – and costs. A sustainable and valuable choice for brands and everyone who packages.

Achieve sustainability objectives conveniently and easily

Sustainability

With our ultrasonic sealing technology, you can enhance the sustainability of your packaging process automatically while simultaneously reducing costs by:

What do elephants have to do with cat food?

A customer packs moist, chunky cat food in a stand-up pouch. This repeatedly resulted in defective packaging that had to be disposed of. By switching to our reliable sealing technology, the number of leaking packs was able to be reduced from 0.05 % to 0.001 %.

That might not sound like much, but it’s actually quite substantial: every day, more than 4.4 tons of cat food are saved from disposal – equivalent to the weight of a full-grown elephant.

Ultrasonic sealing is suitable for a wide range of applications.

Valuable for different applications

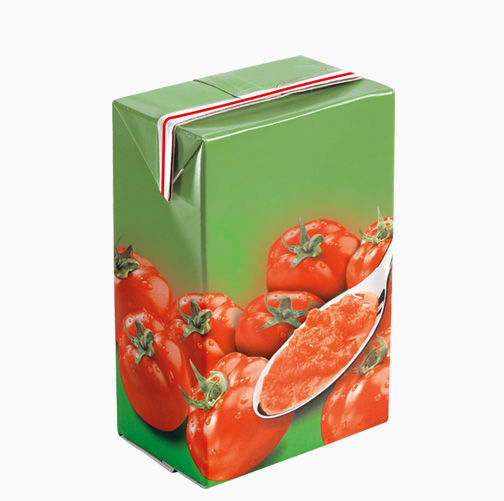

The longitudinal seal on a pillow bag, the top seal or the cap seal on carton or sealing of chain bags, ultrasonic sealing technology provides solutions for a wide range of packaging applications to make your sealing process faster, safer and more sustainable.

Many possible uses

Valuable for different industries

The ultrasonic sealing technology is used to package products in many industries – whenever there is a need for packaging that is durable, leak-proof, and visually flawless.

The ultrasonic generator ensures reproducible results for all sealing applications. With specially developed functions and external sensors, it is possible to reliably detect faulty conditions and eliminate defective sealed packaging.

Ultrasonic sealing offers solutions to meet the demands of the future

Legal regulation for packaging

Whether you are looking to limit overpackaging, increase the product-specific recyclate usage rate, or replace multilayer packaging with new monomaterials, ultrasonic sealing offers a future-proof solution to meet your packaging needs.

Overpacking

EU-wide standards for over-packing will define maximum allowed empty space in packaging and ban certain forms of unnecessary packaging. The Ultrasonic technology allows to minimize the sealing area and as a result reduces unnecessary packaging space.

Recyclate

In the future an increased use of recycled plastics in packaging material is mandatory to meet the legal regulations and to decrease the use of virgin materials.

Monomaterials

In order to meet future packaging recycling rates monomeric materials will become more and more a standard for packaging material. As monomeric material is quite sensible towards heat Ultrasonic offers here the right technology for a tight and reliable sealing process.

INDUSTRY LEADING GUIDE

Discover how to navigate the next era of Sustainable Packaging Innovations! Don’t miss out on these game-changing insights.

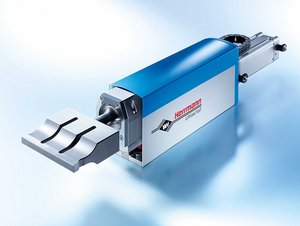

The top seal module from Herrmann brings together the experiences from more than 1,000 top-seal sealing stations on the market. With its modular design, it is configurable for a variety of packaging machine types.

- 30 and 35 kHz operating frequency

- up to 207 mm sealing length

- up to 1200 N sealing force

Herrmann Ultraschall PACKAGING – global market leader, global partner.

How ultrasonic sealing works

In ultrasonic welding, melt is created in the packaging material itself by introducing mechanical vibrations into the packaging material using a sonotrode. These vibrations generate friction between the molecular chains and the interfaces of the packaging material layers, resulting in localized melting. The use of cold ultrasonic tools enables rapid cooling, allowing for immediate loading of the produced seam. This minimizes the thermal load on the materials and the packaged goods.

Leverage our expertise and optimize your packaging process!

Contact us and we will launch a project together that will enable you to incorporate the sustainability megatrend into your company – conveniently, quickly, and cost-effectively.

Contact